Summary of Recent Projects is a condensed overview of some of our projects that Logichem Process International has been contracted to oversee, design and supply equipment over the last few years.

Rheebok Close Wellington Industrial Park

Mon - Thurs: 8am-5pm | Friday: 8am-3pm

+27 21 873 6499

Projects

2023

(In progress, no photos)

2022

2021

2020

2019

2018

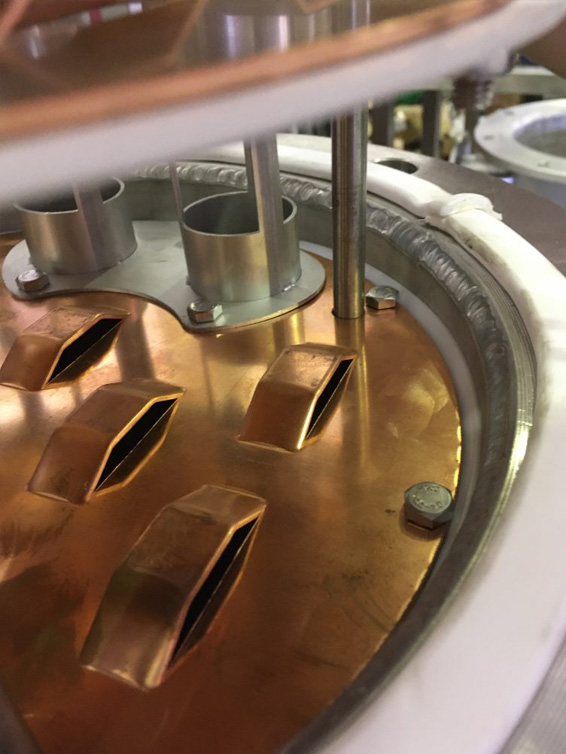

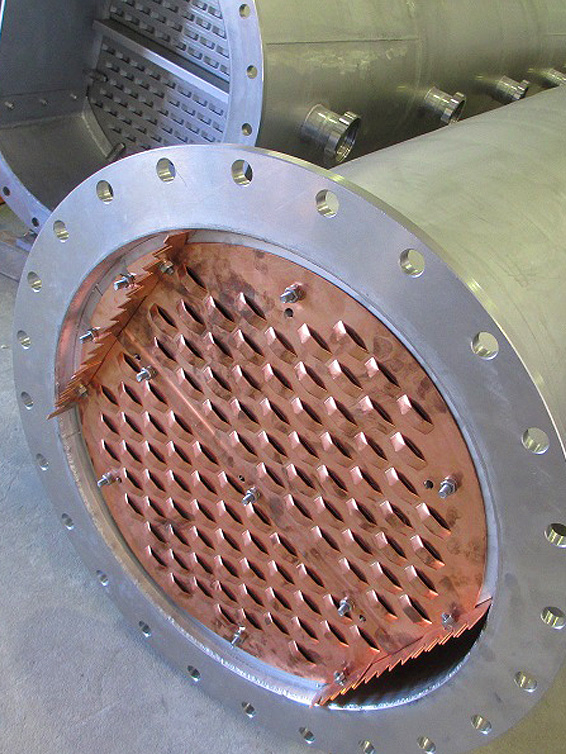

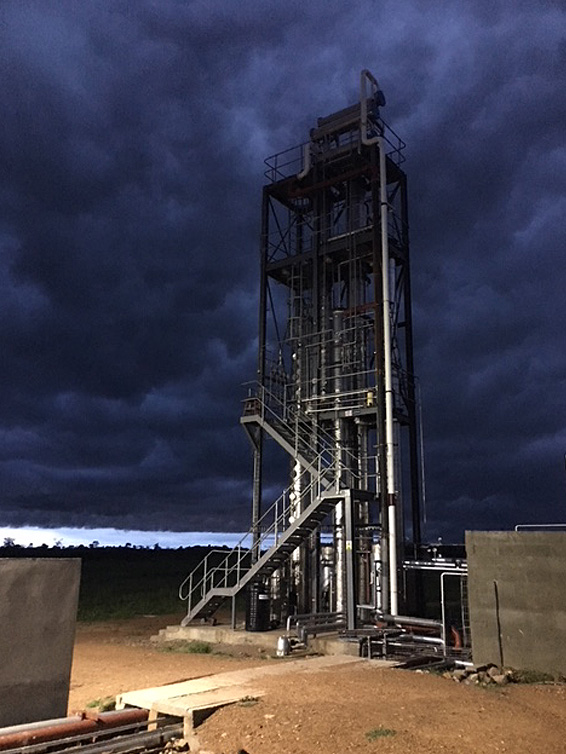

South Africa– Distillery Upgrade

EPCM: EPC management of a distillery upgrade, including a new fermentation cellar, relocation of existing equipment to the new site, upgrade of existing utilities, and integration of new processes into an existing site.

Turnkey: Supply of new distillation column which utilises feed stock with high solids content (fruit based).