Summary of Recent Projects is a condensed overview of some of our projects that Logichem Process International has been contracted to oversee, design and supply equipment over the last few years.

Projects

(In progress = no photos)

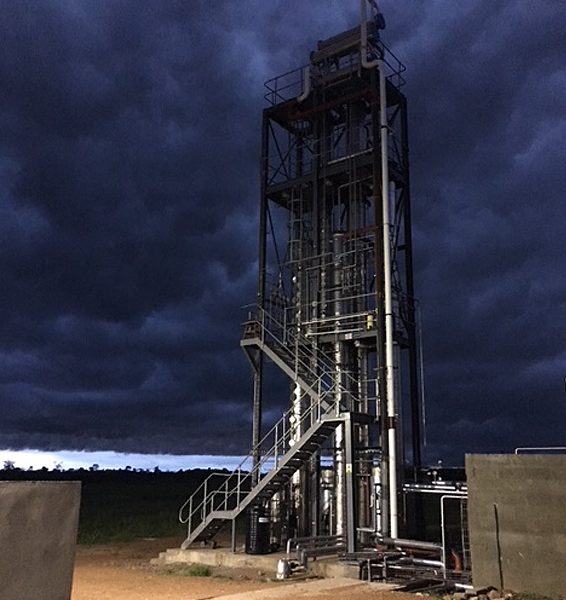

Low & No Beverages – 2200 Wine GoLo & Heat Pump (South-East Australia)

We are excited to unveil our latest innovation: the Heat Pump system.

Developed by Schalk Pienaar, the founder and former CEO of Logichem, this cutting-edge technology has been in the making for nearly 12 years. After two years of testing, we are proud to integrate our new Heat Pump technology to our GoLo Systems.

The GoLo with the Heat Pump is the most energy-efficient dealcoholisation process with the lowest carbon footprint attainable.

We had the privilege to supply a 2200 l/h GoLo with Heat Pump to Low and No Beverages in South-East Australia. The system is up and running, in production since June 2024.

We have two similar systems destined for Australia and North America. We look forward to sharing more on these units soon.

If you would like to learn more about our GoLo or Heat Pump technology, please reach out to us via our contacts page.

DCOOP – 2200 Wine GoLo (Spain)

We’re excited to announce the successful installation and commissioning of another GoLo unit at one of our valued clients’ facilities: DCOOP in Alcázar de San Juan, Spain.

The plant has been in operation since March 2024 and includes an integrated CIP system.

1000 l/h Wine-based Plant (Europe)

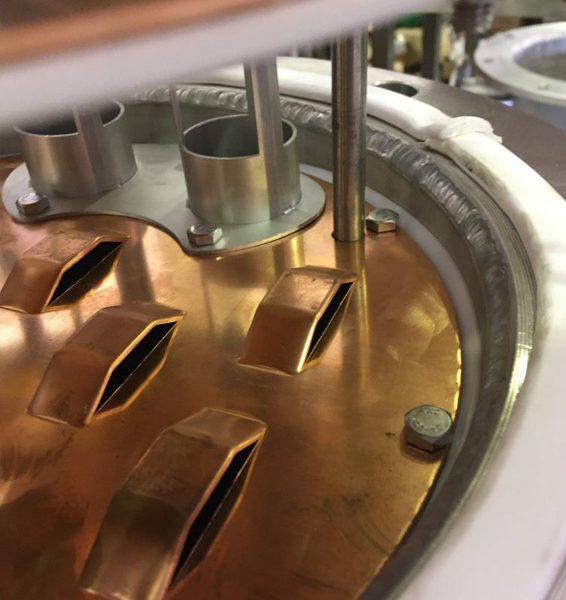

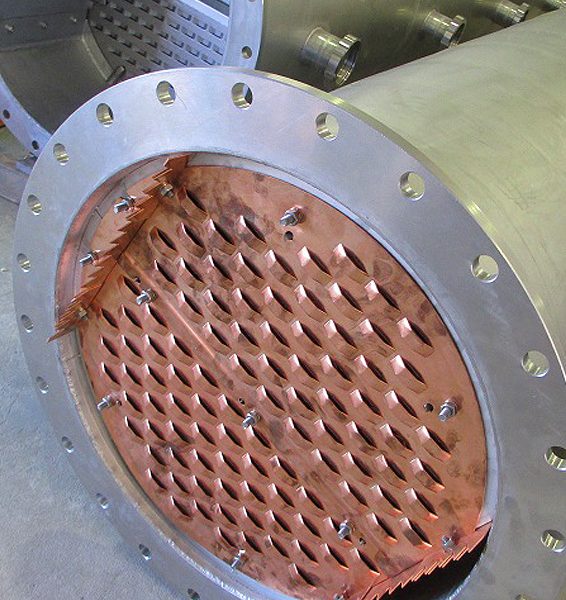

Replacement Wash Column (Worcester, South Africa)

Out with the old, in with the new!

We recently installed a new Wash Column for a local client. This upgrade helps reduce steam usage and is designed to support future capacity expansion in their neutral alcohol plant.

2200 l/h Wine-based Plant with Integrated Heat Pump System (Australia)

Repeat SO2 Vaporiser (DRC)

This SO2 vaporiser is the 6th unit we are supplying since its design in 2011.

It’s fully automated, skid-mounted for easy transportation and installation, and made of mostly 316 stainless steel to handle tough site conditions.

2200 l/h Wine-based Plant with Integrated Heat Pump System (USA)

South Africa – Distillery Upgrade

EPCM: EPC management of a distillery upgrade, including a new fermentation cellar, relocation of existing equipment to the new site, upgrade of existing utilities, and integration of new processes into an existing site.

Turnkey: Supply of new distillation column which utilises feed stock with high solids content (fruit based).