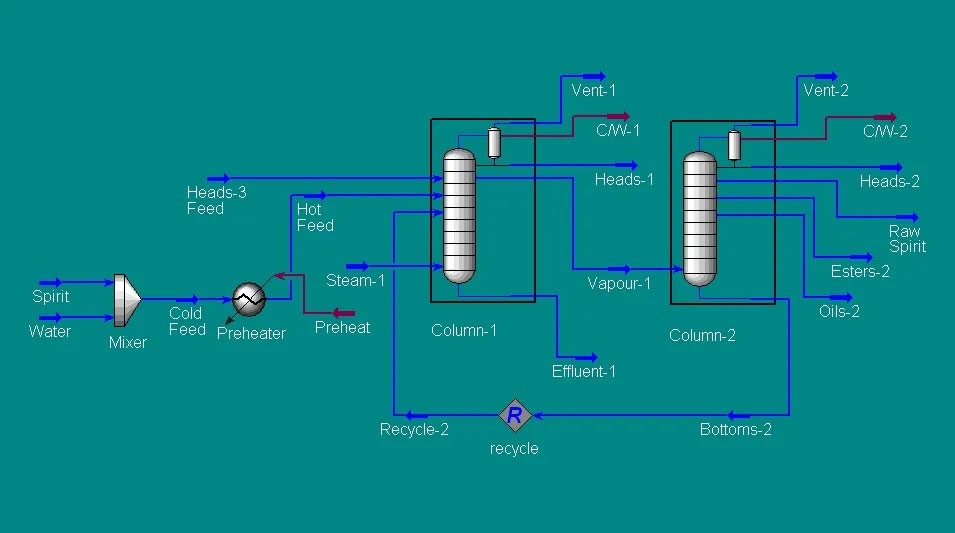

Logichem has a strong Process Simulation capability, which enables us to build accurate, predictive computer-based models of processes.

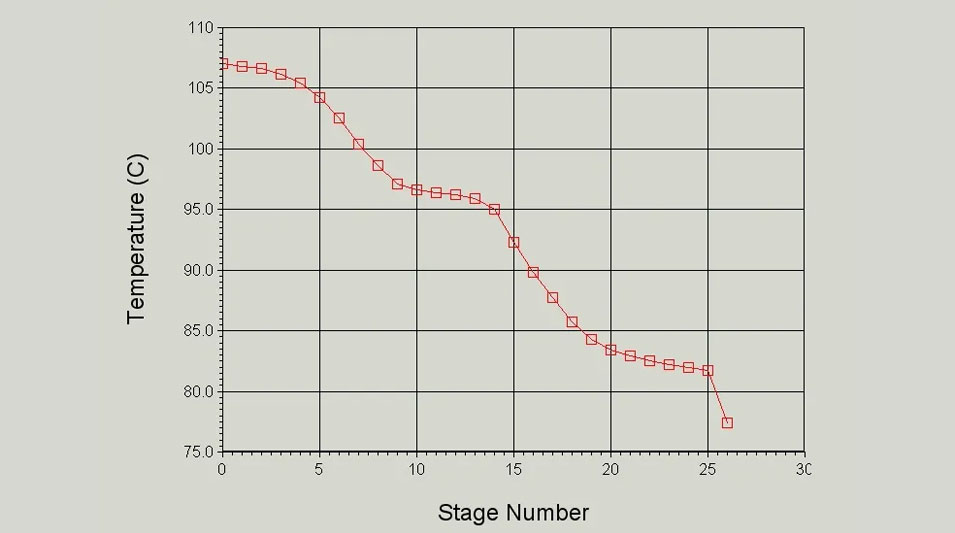

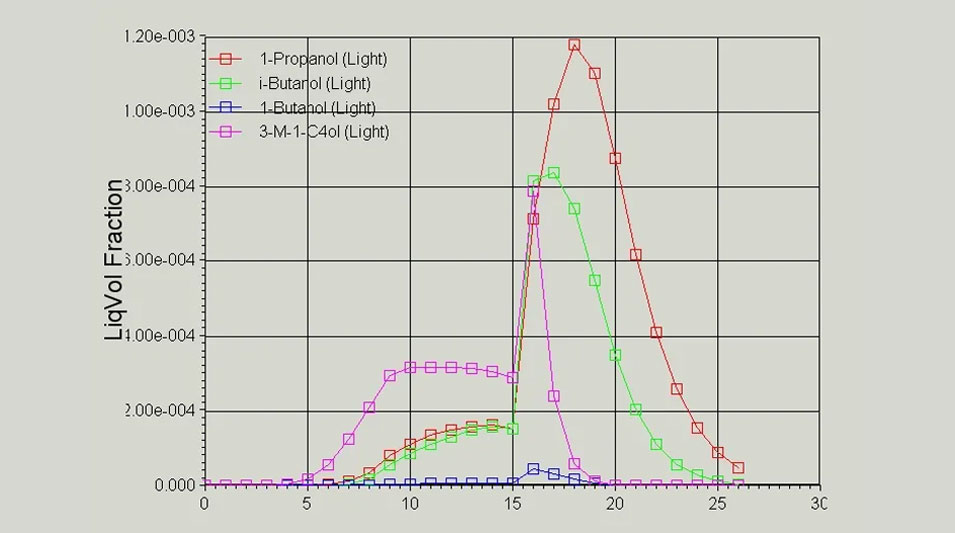

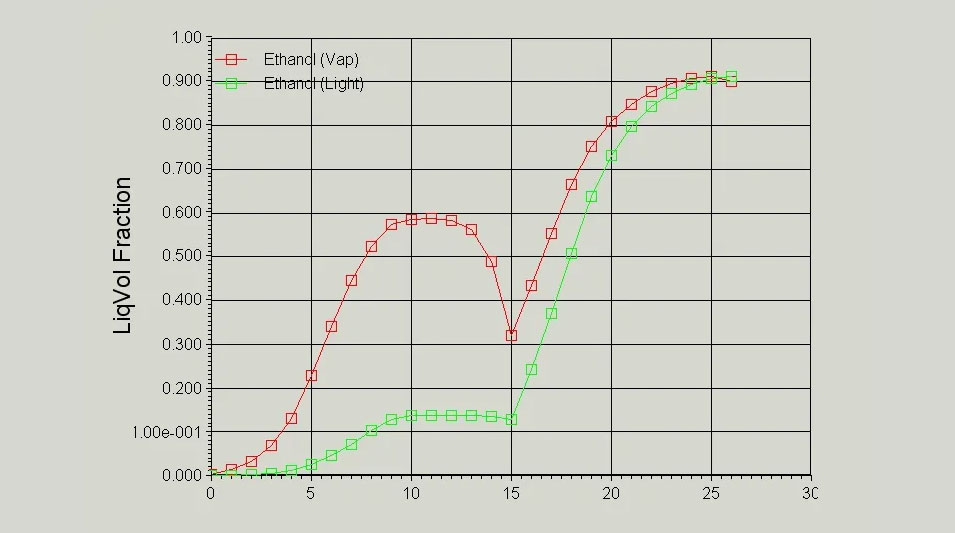

This is a particularly powerful tool used in the development of our alcohol distillation technology. Our Alcohol Distillation models have been validated on actual plant performance data, enabling reliable, predictive evaluations of alternative operating strategies in optimizing our designs to match Client requirements and constraints. This process simultaneously generates accurate Design Data establishing the basis for subsequent Equipment Design and Control Strategies.

Application of this advanced design technique in the predominantly traditional Alcohol industry is the single most important factor that enabled Logichem to become the leading supplier to the Alcohol industry in Southern Africa.

Process Simulation also plays a major role in the development of innovative technology. Examples are Logichem’s propriety CO2 Capture and Purification, and brewery water deaeration technology, installed at a number of breweries and alcohol distilleries in Africa.

Process Simulation, coupled with our experience, is also the most powerful tool in trouble-shooting assignments, efficiency-improving studies, and debottlenecking exercises conducted for Clients. It enables us to pinpoint problem areas and offer optimized solutions.